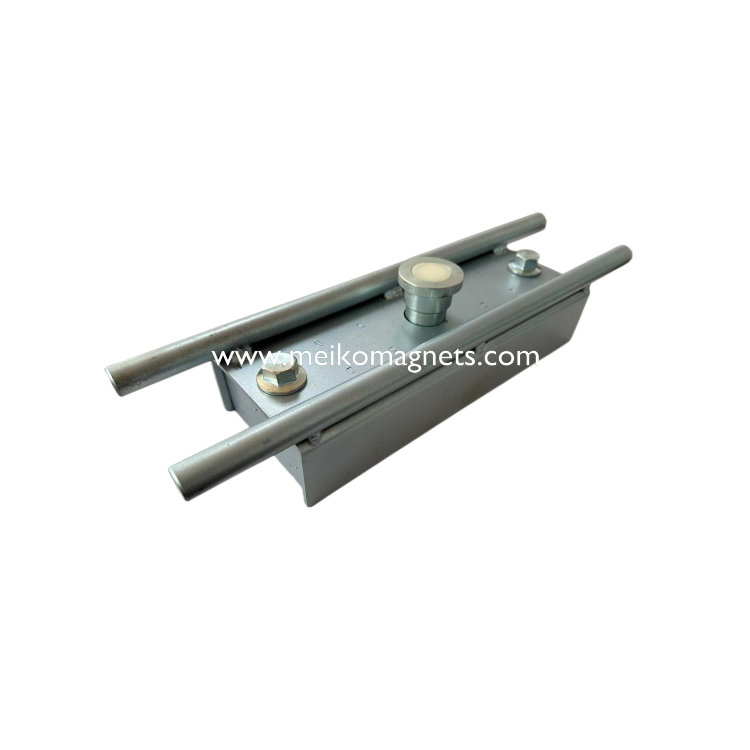

Precast Concrete Push Pull Button Magnets with Sided Rods, Galvanized

Short Description:

Precast concrete push/pull button magnet with sided rods are used to attach on precast mold steel frame directly, without any other adapters. The two side d20mm rods are perfect for magnets to hang on the concrete side rail, no matter one side or both side holding for the combination of rails.

Precast Concrete Push/Pull Button Magnet is the standard magnetic fixing solution for holding precast framework on the steel table. It’s widely used for steel, wooden/plywood frames with or without extra adaptors. This type button magnets with two sided rods could be put into the steel frame directly, no extra adaptors required. It’s produced with steel casing with welded steel rods, and switchable spring button integrated magnetic system. Profiting by the emerged super neodymium magnet block, it could afford powerful and incessancy retaining force against the framework from silding and moving issues.

Owing to maximize the performance of magnetic force, the critical point is to clean out any small crushed concrete or ferrous nails and stuffs under magnet before installation. In front of pushing down the spring button, put the magnets into the right position and make the sided rods hanging on the framework grooves, no more extra welding or bolting needed. The follow-up operation is only to depress the button and it works now. After demoulding, better to use a special lever tool to release the button.

As a professional shuttering magnets manufacturer in China, Meiko Magnetics are serving and participating in hundreds of precasting projects by outputting our professional knowledge and qualified products on magnetic system concerning on precast filed. Here you can find all required magnets for your easier and more efficient fixing solutions in the modular construction.

Standard Dimensions

| ITEM NO. | L | W | h | L1 | M | Adhesive Force | Net Weight |

| mm | mm | mm | mm | kg | kg | ||

| SM-450 | 170 | 60 | 40 | 136 | M12 | 450 | 1.8 |

| SM-600 | 170 | 60 | 40 | 136 | M12 | 600 | 2.0 |

| SM-900 | 280 | 60 | 40 | 246 | M12 | 900 | 3.0 |

| SM-1350 | 320 | 90 | 60 | 268 | M16 | 1350 | 6.5 |

| SM-1500 | 320 | 90 | 60 | 268 | M16 | 1500 | 6.8 |

| SM-1800 | 320 | 120 | 60 | 270 | M16 | 1800 | 7.5 |

| SM-2100 | 320 | 120 | 60 | 270 | M16 | 2100 | 7.8 |

| SM-2500 | 320 | 120 | 60 | 270 | M20 | 2500 | 8.2 |

Advantages

-High Forces from 450KG to 2500KG in small body, save the space of your mold extremely

-Integrated automatic mechanism with steel springs for easier operation

-Welded threads M12/M16/M20 to adapt required form-work fixture

-Multi-functions magnets for different purpose

-Various type of adapters are equipped to match your side rail profile, no matter wooden, plywood, steel, aluminum mold.