Sintered NdFeB magnet is an alloy magnet made fromNd,Fe,B and other metal elements.It is with the strongest magnetism,good coercive force. It’s widely used in mini-motors, wind generators, meters, sensors, speakers, magnetic suspension system, magnetic transmission machine and other industrial applications. Very easy to corrosion in humid environments, so it is necessory to do the surface treatment according customers’ requirements. We can offer the coatings, such as Zinc, Nickel, Nickel-copper-nickel, Silver, gold-plating, Epoxy coating, etc Grade: N35-N52, N35M-48M, N33H-N44H, N30SH-N42SH, N28UH-N38UH, N28EH-N35EH

The Procession of Sintered Neodymium Magnet Manufacturing

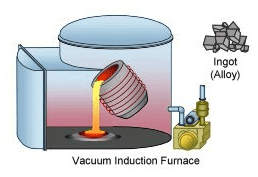

The magnetic raw materials and other metals are exposed to mid frequency and melted in an induction furnace.

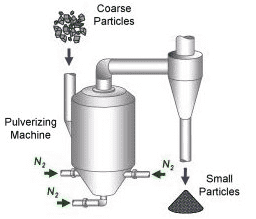

After completion of various process steps, the ingots are pulverized into particles that are several microns in size. In order to prevent oxidation from occurring, the small particles are protected by nitrogen.

The magnetic particles are placed in a jig and a magnetic field is applied while the magnets are pressed into shapes primarily. After initial shaping, oil isostatic pressing will go further to form shapes.

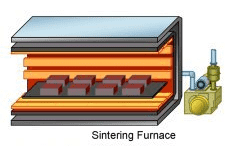

The magnetic particles are placed into ingots that have been pressed and will be heat treated in a sintering furnace. The density of the prior ingots only hits 50% of true density to sintering. But after sinteing, the true density is 100%. Through this process, the measurement of ingots almost shrinks 70%-80% and its volume is reduced by 50%.

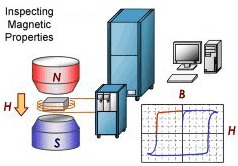

Basic magnetic properties have been set after the sintering and aging processes are completed. The main measurements including remnant flux density, coercive, and maximum energy product are recorded.

Only those magnets that passed the inspection are sent to subsequent processes, like machining and assembling.

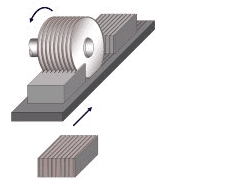

Due to shrinkage from the sintering process, required measurements are achieved by grinding the magnets with abrasives. Diamond abrasives are used for this process because the magnet is very hard.

To best suit the environment in which they will be used, the magnets are subjected to various surface treatments. Nd-Fe-B magnets are generally susceptible to rust with appearance treated as NiCuNi magnet, Zn, Epoxy, Sn, Black Nickel.

After plating, related measurements and visually inspection will be done to confirm our magnet product appearance. Besides, to ensure the high precision, we also need to test the sizes to control the tolerance.

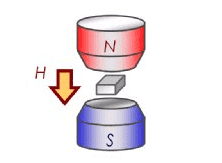

When the appearance and sizes tolerance of magnet qualified, it’s time to make magnetization magnetic direction.

Subsequent to inspection and magnetize, magnets are ready to pack with paper box, even wooden pallet as per customers’ requirements. Magnetic Flux can be isolated by steel for air or express delivering term.

Post time: Jan-25-2021